Essential Maintenance and Care Guidelines to Maximize Lifespan and Performance of PTFE and PTFE Lined Dip Pipes

Understanding PTFE and PTFE Lined Dip Pipes

PTFE, Polytetrafluoroethylene, is an incredible material known for its unique properties. It carries exceptional non-stick qualities. It is highly resistant to chemicals. Therefore, it is an ideal solution for multiple industrial applications.

PTFE Lined Dip Pipes are created by lining in a metal pipe with PTFE inside/outside. The protective layer helps the metal from abrasion, wear and harsh substances. The layer aims at extending the lifespan of the pipe. PTFE lined dip pipes are extensively used in various industries such as pharmaceuticals, chemicals, and wastewater treatment, especially the industries where corrosive environment is prevalent.

How To Improve the Life of PTFE Or PTFE Lined Dip Pipes

Regular Inspection for PTFE or PTFE Lined Dip Pipe:

It is essential to carry out regular visual inspection to maintain the health of your PTFE or PTFE lined dip pipe. When a team of professionals keeps examining its surface closely, they can easily identify signs of damage, wear or corrosion. They can detect potential issues early on before they turn into significant problems. Here, you need to check for cracks, scratches or discoloration – these may indicate underlying issues that require more attention. Staying vigilant and addressing crucial issues in a prompt manner can help you to prevent expensive repairs. This is fundamental to ensuring the seamless reliability of your piping system.

Careful Handling to Preserve Integrity:

During the installation and handling process, it is necessary to handle PTFE or lined dip pipe with utmost care and precision. The professionals must avoid giving them rough treatment or creating an impact that may damage the protecting lining. Such pipes need gentle care. The team must utilize appropriate tools and equipment to make sure they are intact. When you treat these pipes with care from the outset, you could avoid potential damage and also prolong lifespan.

Understanding the Limits:

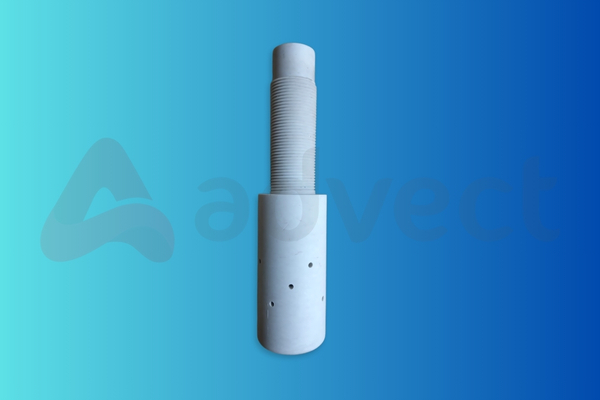

PTFE and PTFE lined dip pipes have their limits in terms of pressure and temperature even though they are durable. When you expose them to extreme conditions that go beyond recommended range, you end up weakening their material after a period of time. This can lead to premature wear, potential failure and inefficiency. Therefore, it is advisable to adhere to the manufacturer’s guidelines with respect to temperature and pressure limits. This is fundamental to ensuring the longevity of the pipes. In case of PTFE sparger with dip pipe, user need to careful about liquid density and solid particles in side process fluid. Sparger holes are mainly used for spray of material or purging gas inside reactor.

Avoid Abrasive Materials:

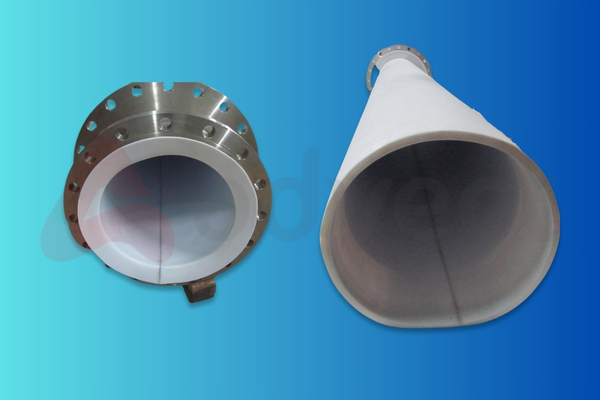

Pipes are vulnerable to damage associated with abrasive materials. When you use PTFE or PTFE lined dip pipes with substances with abrasive particles, you may end up wearing down their protective lining. This contact can also reduce their effectiveness in preventing wear and corrosion. It is better to be careful by avoiding using abrasive materials with these pipes. This will help you to preserve the integrity of the protecting lining, a crucial step in extending the lifespan of your pipes. In case of minor cracks or holes in some cases its possible to weld it with FEP or PFA mainly in reducing flanges or other parts if it’s made of similar material. For corrosive flanges or pipes, its advisable to remove and paint it property to avoid surface damaged due to corrosive atmosphere outside of vessel or GLR.

Preventive Maintenance to Preserve Longevity:

Regular cleaning and maintenance are necessary to keep your pipes in reliable condition. It is important to regularly remove built-up debris, residues or contaminants accumulated on the surface of PTFE lined dip pipes so as to prevent corrosion. This is the easiest way to ensure the longevity of the protective lining. Often, companies establish a proactive maintenance schedule and adhere to them to stay head of the potential issues.

Regular Testing to Maintain Performance

Frequent testing and monitoring are crucial to assess the condition of your PTFE or PTFE lined dip pipes. Here, you need to conduct non-destructive tests which can include visual inspections, spark testing and hydro testing to detect leakage in side sealing etc. to identify abnormalities or defects, if any, early on. This will help you to facilitate timely intervention, and thus prevent costly replacements or repairs. Make sure to regularly test and monitor your pipes and they continue to deliver desired reliability and performance.

Following Manufacturer's Recommendations:

The last step is to adhere to the manufacturer’s recommendations for comprehensive care and maintenance. The top-notch manufacturers are knowledgeable for their products. They are the best in terms of providing valuable guidance and insights on how to maximize the performance of your pipes. When you follow their consulting or recommendation, you can make sure that your piping system is in optimal condition for many years.

Tailored Process Solutions & Precision Equipment – Advect Process Systems

Advect Process Systems Canada Ltd. empowers industries with top-notch, reliable process solutions and consultative engineering services. We serve clients around the globe, the clients in pharmaceutical, chemical, engineering and equipment companies. Our solutions are tailored to meet their needs. We offer a comprehensive range of process equipment that withstand the rigors of chemical processing. Our valves are precision-engineered to provide you with great chemical compatibility. We offer versatile PTFE solutions that promise exceptional performance.

Advect Process Systems' PTFE Lined Dip Pipes for Corrosive Fluids

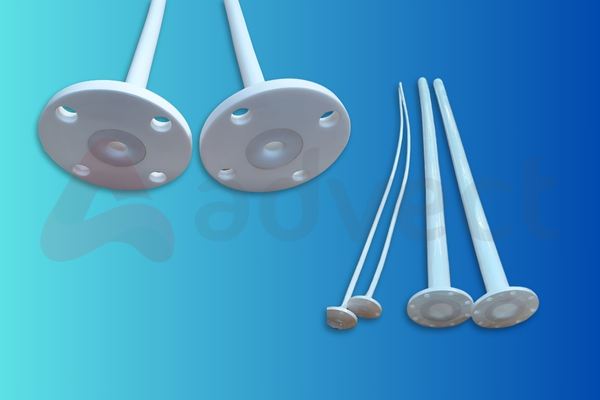

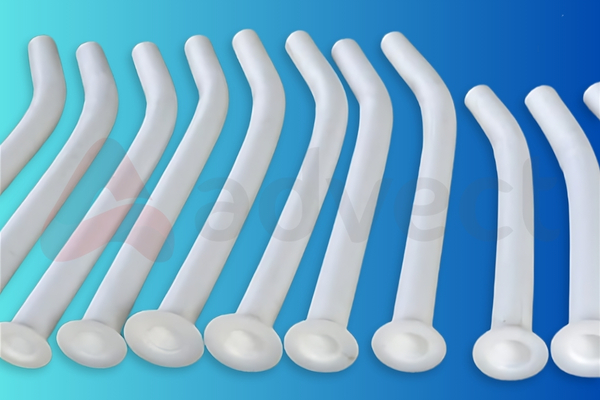

Our PTFE lined dip pipes can withstand the test of time as they reflect superior engineering. They are primarily crafted to convey highly corrosive fluids. PTFE lining ensures optimal fluid flow. It offers a great level of structural stability. During the manufacturing process, we make sure to follow all applicable codes and standards. We take into consideration various factors such as pressure testing load, operating load, agitation load, etc. Moreover, we make sure to offer customizable features to our clients such as lugs, earthing studs, vent extensions, etc. Fulfilling their exact requirements is what we work for at Advect Process Systems. We construct dip pipes from carbon steel; therefore, they offer excellent mechanical strength. They are ideal for glass-lined reactors. We offer custom designs for non-standard applications. Our product consists of various designs of PTFE lined dip pipes like straight dip pipe for impeller agitator, inclined dip pipe for anchor agitator GLR, PTFE dip pipe with sparger is for gas purging application inside reactor. Dip pipe with PTFE spray ball is mainly use for cleaning of GLR from inside after few batches of reaction and also multiuse of dip pipe.

Solid PTFE dip pipe or Solid drop tube are mostly smaller in length and made of pure PTFE Only. J type drop tubes or J type ptfe dip pipes are mainly used for flow to particular location in side reactor. Sometimes its also to property locate far from anchor agitator. PTFE Feedpipe are mostly in columns used for liquid inside column equipment and mass transfer equipment. Dip pipe sizes mainly depends on glass lined reactor nozzles, or tanks or column nozzles but as a standard size we can offer from 1” to 16” diameter including large diameters dip pipes for sulphuric acid plants.

Discover Our More PTFE Products

- PTFE Lined Pipe

- PTFE Lined Bend

- PTFE Lined Reducer & Reducing Flange

- PTFE Lined Tee/Cross

- PFA lined Instrument Tee

- PTFE Lined Pipe

- PTFE Lined Sight Glass

- PFA Lined Ball Valve

- PFA Lined Plug Valve

- PFA Lined Diaphragm Valve

- PFA Lined Butterfly Valve

- PFA Lined Flush Bottom Valve

- PTFE Expansion Joints / PTFE Bellows

- PTFE Liner / PTFE Tubes

- PTFE Sheet