Forging

We specialize in the manufacturing and supply of a wide range of forging components and parts. Our expertise encompasses various industries, including automotive, aerospace, oil and gas, construction, and more. With a team of skilled engineers and state-of-the-art facilities, we ensure that each component meets the highest standards of quality and performance.

Our ISO 9001:2015-TUV Nord-certified manufacturing facility in Rajkot, India, is well equipped to offer all three forging types. Open-Die Forging, Closed-Die Forging, and Roll Forging

Our forged components undergo rigorous quality control measures, including inspections for defects, dimensional accuracy, and material integrity. This ensures that the final products meet industry standards and customer specifications.

Our products based on forging types and applications

Basics of forging

Forging is manufacturing process where metal is pressed, pounded or squeezed under great pressure into high strength parts known as forgings. The process is normally (but not always) performed hot by preheating the metal to a desired temperature before it is worked. It is important to note that the forging process is entirely different from the casting (or foundry) process, as metal used to make forged parts is never melted and poured (as in the casting process).

The forging process can create parts that are stronger than those manufactured by any other metalworking process. This is why forgings are almost always used where reliability and human safety are critical. But you'll rarely see forgings, as they are normally component parts contained inside assembled items such as industries like bearings, automobiles, tractors, ships, oil drilling equipment, engines, missiles and all kinds of capital equipment to name a few.

Example of Forging Parts

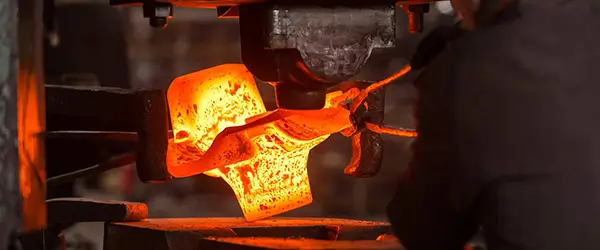

Types of Forging

Closed Die Forging

Precision shaping from ounces to 50,000 lbs, handling diverse materials for versatile strength. Crafted with expertise for components that exceed industry standards.

Open Die Forging

Dynamic shaping of metal from pounds to 150 tons. Versatile process for forgeable alloys, ensuring structural integrity in substantial components.

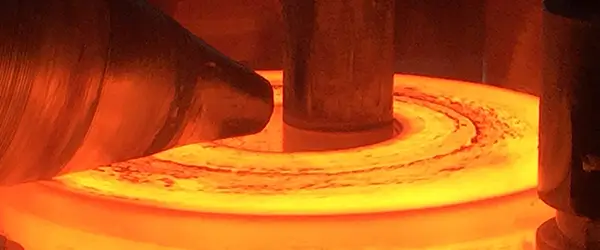

Seamless Rolled Ring Forging

Seamless rolled ring forging shapes robust, ductile rings for various applications, from gears and engine bearings to couplings and pressure vessels.

Cold Forging

Cold forging, covering processes like bending and coining, shapes parts at temperatures from room temperature to several hundred degrees.

Applications

Agriculture

Fluid Handling

Food Processing

Government & Military

Lifting & Swivels

Mining

Oil & Gas

Pumps & Valves

Rail Road

Transportation