How to handle failure of PTFE lined pipes and fittings

Reason of failure – defective pump, reactor, process malfunction, chemical reaction, sudden rise of temperature or pressure. Human error, valve failure, sensor defect or maintenance error.

Lined piping failure detection, early detection of lining failure can be seen on vent hole given on pipes and fittings. In case of early detection there are chances that batch or material under process can be saved from mixing of corrosion with process fluid or spillage of material on floor.

During the inspection, first step is to stop process or plant so failed lined pipe or fittings can be replaced. It is also recommended for inspection of all the nearby connected lined pipes and fittings since there are chances that if failure was due to pump or any external reasons then there are chances that other piping would also be damaged and need to be replaced.

Once lined product uninstalled, it is mandatory to check first what process its used and how hazardous that chemical for human contact or it may have material which creates gas and that’s harmful. After checking if its safe to check and if possible better to clean it for surface inspection.

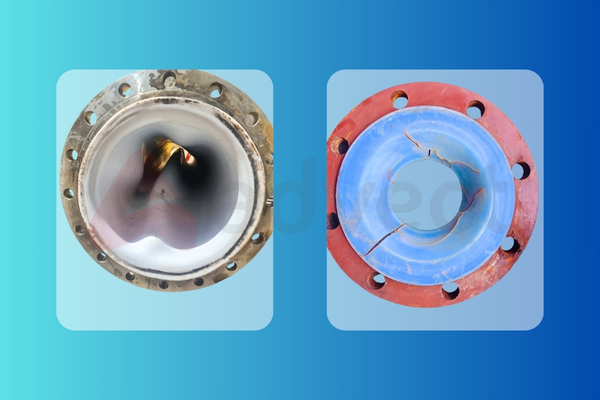

In some cases of failure where due to high pressure or high vaccum lining damaged, we see change of shape of lining so during cleaning or inspection, it would be better not to change for further evaluation in case required because maintaining same condition will be helpful to understand engineer reason of failure.

While doing inspection, its better to note operating parameters exactly and also process fluid and properties of material. In case of failure of welding or metal portion, there are chances that quality of welding was poor or due to highly corrosive nature of fluid after lining failure weld joint got weaker and metal part damaged.

Depending on the situation, its better to take pictures of failure even before uninstalling and after removal from the piping.

Common type of lined pipe and fittings failure

Discover Our More PTFE Products

- PTFE Lined Pipe

- PTFE Lined Bend

- PTFE Lined Reducer & Reducing Flange

- PTFE Lined Tee/Cross

- PFA lined Instrument Tee

- PTFE Lined Pipe

- PTFE Lined Sight Glass

- PFA Lined Ball Valve

- PFA Lined Plug Valve

- PFA Lined Diaphragm Valve

- PFA Lined Butterfly Valve

- PFA Lined Flush Bottom Valve

- PTFE Expansion Joints / PTFE Bellows

- PTFE Liner / PTFE Tubes

- PTFE Sheet